Performing regular nozzle checks and cleanings is an important part of maintaining your Sawgrass SG500 printer. A nozzle check allows you to identify any clogged or malfunctioning nozzles in the printhead so you can take steps to clear them before they cause print quality issues. Read on for a step-by-step guide to running nozzle checks and interpreting the results.

The Sawgrass SG500 is a popular desktop dye sublimation printer used for printing custom graphics onto blanks like mugs, shirts, phone cases and more. Like all inkjet printers, the printheads can accumulate dried ink, dust and debris over time which can clog the tiny nozzles and prevent them from firing properly. This will show up as gaps or light bands in your prints.

That’s where nozzle checks come in! A nozzle check prints a small test pattern that lets you visualize the health of each nozzle. If any nozzles are clogged it will be immediately obvious. The good news is the SG500 also has a built-in cleaning utility that can often clear clogged nozzles. Catching issues early with regular nozzle checks allows you to keep your print quality flawless.

In this guide you’ll learn:

- How to access the nozzle check utility on the Sawgrass SG500

- How to interpret the nozzle check pattern

- When to run cleaning cycles if clogged nozzles are found

- How to perform a manual head cleaning if needed

- Tips for preventing future clogs

Whether you run your SG500 every day or just on weekends, adding periodic nozzle checks to your routine is easy and ensures your printer continues churning out perfect prints. Let’s get started!

Step 1: Accessing the Nozzle Check Utility

On the Sawgrass SG500, the nozzle check feature is built right into the printer software. Here’s how to access it:

- Make sure your printer is powered on and connected to your computer. Open the Sawgrass Print Manager software.

- Click on the “Maintenance” tab at the top.

- Look for the “Nozzle Check” box on the left side and click on it.

- Make sure letter size paper is loaded in your printer. Click the “Print” button.

The printer will now print a small test pattern. Let’s look at how to interpret it.

Step 2: Reading the Nozzle Check Pattern

The nozzle check pattern prints diagonally across the page and consists of multiple horizontal lines representing each nozzle in the printhead. Here’s what normal output should look like:

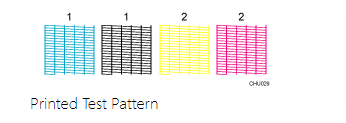

Using the test pattern, check for print head clogging and the number of the clogged head.

The number appearing above each color in the test pattern is the number of the print head.

The print head for Cyan and Black is [Head 1].

The print head for Yellow and Magenta is [Head 2].

Check which print head is clogged by referring to the following illustration.

A solid line indicates the nozzle is clear and firing correctly.

Gaps or breaks in the line indicate a potential clogged or malfunctioning nozzle.

Check the pattern closely for any inconsistencies. Even small gaps can translate to degraded image quality. If the pattern prints cleanly without any breaks, your nozzles are in good shape and no cleaning is required.

If you do notice gaps, proceed to running cleaning cycles as described in the next section.

Step 3: Running Cleaning Cycles for Clogged Nozzles

If your nozzle check reveals clogged nozzles, don’t panic! The SG500 has an automated printhead cleaning utility that can often clear them out.

Here’s how to run cleaning cycles:

- Remain in the Maintenance section of the Sawgrass Print Manager software.

- Locate the “Cleaning Cycles” box and click on it.

- Click the “Heavy Cleaning” button. This will run a deep cleaning routine.

- When prompted, load a sheet of paper to act as a blotter. This absorbs excess ink flushed from the printhead.

- The printer will run its cleaning routine, forcing ink through the nozzles to unclog them. This may take a few minutes.

- When complete, run another nozzle check to confirm the cleaning worked. Review the pattern – the gaps should now be filled.

- If gaps remain, repeat the cleaning process up to 2 additional times. This resolves most clogs.

- If heavy cleaning cycles don’t fix the issue, proceed to manual cleaning next.

With diligent cleaning cycles, the vast majority of clogged nozzles can be restored to normal function. The key is catching them early before permanent clogs form.

Step 4: Performing Manual Head Cleaning

In rare cases where automated cleaning cycles don’t clear clogged nozzles, some manual maintenance may be required. Here are the steps:

Gather supplies:

- Cleaning kit included with your SG500

- Distilled water

- Lint-free cloths

Manual cleaning steps:

- Open the printer and locate the printhead. It sits towards the back behind a protective cover.

- Slide the printhead cover off to expose the nozzles. Do NOT touch them.

- Dip the included swab lightly in distilled water. Gently dab the moistened swab across the nozzle area to loosen dried ink.

- Next, use the syringe from the cleaning kit to flush distilled water through the nozzles. Aim it directly into the tiny openings.

- Allow the printhead to air dry completely before reinstalling the protective cover. Never power on the printer with a wet printhead.

- Test nozzles again. If gaps persist it’s time to replace the printhead.

Manual cleaning gives clogged nozzles a second chance, but proceed gently and with care. Avoid excess wiping or scrubbing and NEVER use cleaning agents except distilled water.

With this deeper cleaning, your SG500 should be back to printing beautifully once more!

Step 5: Preventing Future Clogs

Now that you’re a nozzle check expert, here are some tips to avoid clogs coming back:

- Run nozzle checks before important print jobs or if you notice print quality declining. Don’t wait until there are visible gaps.

- When not printing, keep the printer powered on so the printhead remains warm. Turning it on and off frequently allows ink to cool and solidify in the nozzles.

- Seal and store your SUB inks properly between uses. Keep them away from extreme temperatures.

- Clean around the printhead periodically with a soft brush to prevent ink buildup.

- Replace printheads after around 3,000 ml of ink use or if cleanings become very frequent.

- Consider a humidifier if printing in a very dry environment. Moisture keeps nozzles from drying out.

Consistent nozzle checks and proper maintenance will keep your SG500 printing like new for years of service. Well-functioning nozzles equal perfect prints!

Now that you know how to check them and clear any clogs, you can keep your printer in top shape. Refer to this guide anytime you need a refresher. Happy printing!

Related: How to Connect Sawgrass SG500/SG1000 Printer to WiFi

Frequently Asked Questions

How often should I do a nozzle check?

It’s smart to make nozzle checks part of your routine maintenance. Check them every 1-2 weeks at minimum, especially if you use the printer daily. Always check before large or high quality print jobs.

What causes clogged nozzles?

Infrequent use, powering the printer on and off, dust, dried ink and general wear over time can all lead to clogs. The tiny nozzle openings are very delicate. That’s why regular checks are key.

Can I clean just one clogged nozzle?

Unfortunately not – the cleaning cycles flush all nozzles at once. But take another close look at your check pattern, often times neighboring nozzles compensate for a clog so you may not see a visible defect in prints yet.

What if heavy cleanings don’t work?

The manual cleaning steps outlined earlier should resolve even stubborn clogs in most cases. As a last resort you can replace just the printhead itself which is more affordable than a whole new printer.

How can I prevent future clogging?

Frequent nozzle checks, proper ink storage, keeping the printer on and maintained, and replacing printheads at the recommended intervals will minimize clogs down the road.

Related: Sawgrass Virtuoso SG500 Sublimation Printer Review

Conclusion

Regular nozzle checks help keep your Sawgrass SG500 printing in tip-top shape for all your dye sublimation needs. By periodically running test prints and cleaning cycles, you can stay ahead of any clogs or malfunctions before they ruin your prints.

Keep this step-by-step guide handy for performing checks, interpreting results, and clearing out any blocked nozzles that arise. Here’s a quick recap:

- Access the built-in nozzle check utility via the Print Manager software

- Examine the printed pattern closely for gaps indicating clogs

- Use the cleaning cycles to automate printhead cleaning

- Try manual cleaning if regular cycles are insufficient

- And prevent future clogs with good maintenance practices

While nozzle checks add a minor step to your routine, they pay off by letting you identify and resolve issues early and painlessly. Consistently flawless prints are worth the small amount of regular upkeep.

Your Sawgrass SG500 represents a notable investment, so be sure to keep those nozzles in check and the printer will deliver reliable performance for many years. Dazzling, professional-quality prints are just a few clicks and checks away. Happy printing!